Share this review

If you haven’t noticed yet, there is a hole in your anvil. Wait, wait, it’s not a manufacturer’s fault. This hole is called the hardy hole, and this is where a variety of blacksmith hardy tools go in.

All of these hardy tools come with a shank that fits in the hole. A wide range of hardy tools are available in the market, and each one is used for a different purpose.

From cutting, bending, and flattening hardy tools, to specialized cone hardy, mushroom hardy, and end scroll hardy, a lot of varied options are available.

As these tools are fixed in the hardy hole, they allow better control and precision. Moreover, working with a fixed hardy tool is much more convenient than bending or twisting stuff on a vise.

Below is a list of some of the essential hardy tools that you must have in your blacksmith workshop.

The best cutting tool for blacksmiths

It is perfect for cutting hot metal stock. The sharp cutting edge can also be used to cut bar stocks and steel pipes.

Why do we like it?

This anvil hardy tool from Rusty and Weathered is specifically forged for cutting hot metal. This 2″ cutter comes with a ¾” shaft. The construction is pretty much straightforward—a wedge-shaped construction with a hardy shank on the bottom.

For the required strength and toughness, this cutting tool is made from high carbon steel. The product has been carefully crafted for the utmost precision and accuracy.

How to use this blacksmith hardy tools? No rocket science here.

You just have to place it in the hardy hole of your anvil. After that, put the sufficiently heated stock on top of it and hammer it.

For the price, this product is an excellent choice for beginners and experts alike. Although you can forge your own hardy cut tool but having one around from the start is a good option.

Pros

Durable high-carbon steel construction.

2″ height with a ¾” shaft.

Cons

Might be too small for some users.

Best flatter hardy tool

Using this tool, you can get rid of all the dips and surface irregularities on any metal sheet. Moreover, the robust construction can take one hell of a beating.

Why do we like it?

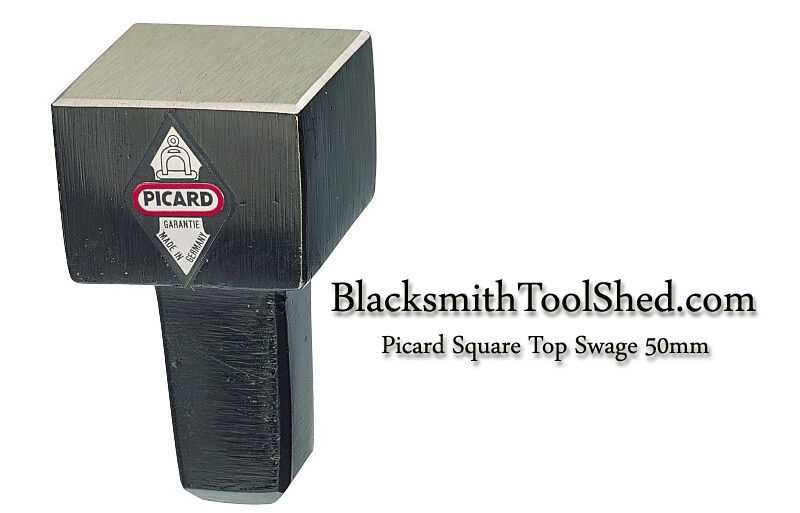

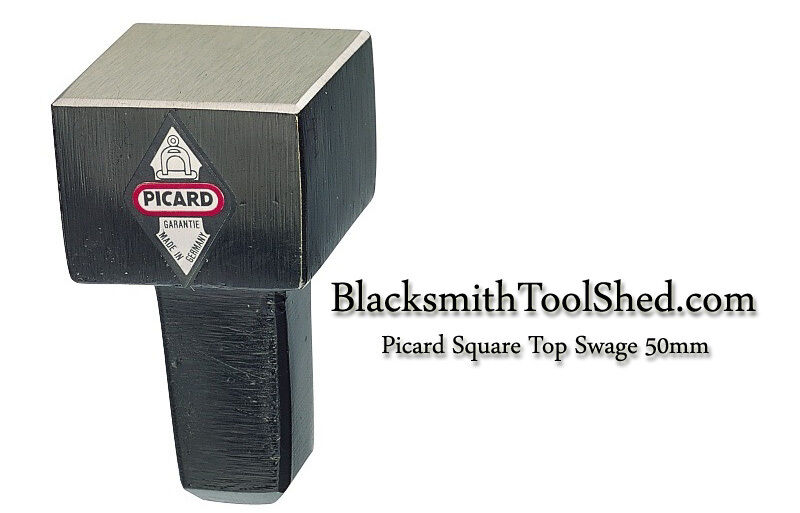

Picard is one of the most reputable manufacturers when it comes to metalworking tools. This flatter hardy tool is more like a bottom fuller. Nevertheless, outstanding toughness and strength allow all types of heavy-duty forge work.

The top of this product is a solid square-shaped working surface. It has an edge-to-edge length of 2″. Also, the hardy shank is 1″ long with a square shape.

It might not fit in your anvil’s hardy hole right away. After some minor grinding and adjustment, it will fit in properly.

You can use this blacksmith hardy tool for flattening metal stocks or for removing bumps and dips.

Yes, being a Picard product, it is expensive as hell. If you have the budget, there is no better option than this one.

Pros

Made in Germany.

Reliable and tough.

Cons

Expensive.

An affordable bending hardy tool

Scrolling, twisting, and bending, this tool ticks all the boxes. Moreover, the 0.98″ hardy shank provides a steady grip for precision bends.

Why do we like it?

If you plan on forging scrolls, s hooks, or anything that requires bends, this hardy tool is a must. The construction is almost similar to a bending fork—two vertical poles with a thickness of approximately 0.75″ each.

The overall length of this blacksmith hardy tool is around 6.16″. The gap between the vertical poles is 1″. This gap is really important, as this is where a bar stock is placed for bending purposes.

Meaning, anything more than 1″ thickness cannot be placed inside. The poles are 2.5″ long each.

How to bend bar stocks? It is quite easy.

First, you have to place the sufficiently heated bar stock inside the 1″ gap between the tuning forks. Now, you can either use your hands, a hammer or even bending wrench.

The tool has been made from high-grade cold-rolled steel (1018) for extra strength and toughness. All in all, this product maintains a perfect balance of quality and price.

Pros

Mild/Low carbon 1018 steel build.

0.98″ hardy shank.

Cons

The welds between the shank and poles are low-quality.

Everything we recommend

The best cutting tool for blacksmiths

It is perfect for cutting hot metal stock. The sharp cutting edge can also be used to cut bar stocks and steel pipes.

Buying options

Best flatter hardy tool

Using this tool, you can get rid of all the dips and surface irregularities on any metal sheet. Moreover, the robust construction can take one hell of a beating.

Buying options

An affordable bending hardy tool

Scrolling, twisting, and bending, this tool ticks all the boxes. Moreover, the 0.98″ hardy shank provides a steady grip for precision bends.

Buying options

The research

Are there any other hardy tool apart from these three?

Can hardy tools be used in a vise?

Are there any hardy tools for cold use?

Who should get this?

Hardy tools are used by every blacksmith. Be it bending, cutting, twisting, or god knows what operation, you will have a hardy tool for it. And yes, you can forge your own hardy tools.

Blacksmiths, jewelers, bladesmiths, knifemakers, or anyone who requires bending, cutting, and twisting stuff should get this.

How we picked?

When it comes to hardy tools, there are some factors one should consider before buying.

- Toughness: Hardy tools go through immense stress and high temperatures throughout their lives. If a tool is made from low-grade steel, it will not last. We have carefully evaluated the tensile strength and hardness of all these tools.

- Hardy Shank Size: We wanted these hardy tools to fit in almost all anvils. The 1″ size can be accommodated by most of the anvils.

- Intended Use: Hardy tools come in different shapes and sizes. Each tool is made for a specific operation. We have included the most basic of them that a beginner should have in his workshop.

Care and maintenance tips

The majority of hardy tools are designed for hot work. Make sure you’re wearing the proper protective gear. Keep all your hardy tools protected from rust by storing them in a dry environment.

Are there any other hardy tool apart from these three?

Yes, and tons of them. Hardy swage, swan neck hardy, dog bone swage hardy, cone hardy, hardy butcher tool, and many others.

Can hardy tools be used in a vise?

Yes, the majority of them can be used with a vise. But the grip and stability offered by an anvil are far better.

Are there any hardy tools for cold use?

Yes, some hardy tools are also designed for cold use. For instance, the cold-cut hardy is short and thick with a tempered build. The obtuse angle helps in cutting cold stocks.

Conclusion

As you progress in your blacksmithing journey, you will realize that hardy tools are of great importance. There will be times when you will forge your very own specialized hardy tools for specific jobs.

Initially, you should at least have these three hardy tools, and most of the projects require some sort of cutting, flattening, and bending of stocks.

Before making the final decision, make sure the tools are designed for the intended use.